I found handmade brass goggles in the net.

For example, this, Last Exile goggles by gogglerman.

He contributed some handmade goggles. I think that I may be able to make such one.

Probably I can't make so complex mechanism.

I tried making simple one.

At first I made paper form for goggles. Then they were glued on the brass sheet which thickness of 0.5mm and were sawed.

The frames were made from brass sheet which thickness is 1.5 mm. They are heavier. I made these parts again from thin sheet.

It took much time because of the thickness 1.5 mm is too thick.

I should change the board of work bench. Stable bench is needed for fine work.

preparing for silver soldering

after that, they are cleaned with acid.

I didn't have a few kinds of silver solder which work with each temperature. So this soldering was a bit hard.

I could imagine what I can do it. When I did it actually, I was pleased with that.

Preparing for silver soldering needs more time.

My skill of silver soldering may become a bit high.

At least, I need 2 kinds of silver solder.

Making screws.

Soldered with this setting.

They are acrylic clear board. It's easy to drill those edges.

This way of attaching clear board to brass goggle is my way, I think.

The way of attaching the leather cushion is wrong. they don't work as cushion.

Spring dumper. They are too heavy.

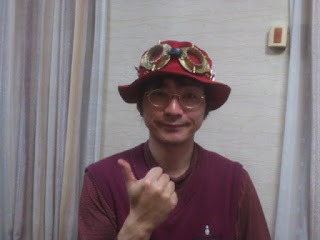

The size is too big !? But I can see my both side.

Using as accessory on the hat is better. That means these one isn't usable.

stitching smaller square is a bit hard.

Memo about inline skates, bicycle, programing, study of japanese ancient music, ancient music of chinese tang dynasty

4 Apr 2016

Brass buckle

I made brass keys for my made baroque style woodwinds. I may make the other thing from the brass with the technique.

How about buckle for leather belt ? I don't have good leather belt yet. I tried making it.

The thickness of the brass sheet is 1 mm. round brass and copper tube are prepared.

Silver Soldered.

after soldering, it is cleaned with detergent for toilet which includes acid.

No polishing may be good.

4 mm brass rod is hard.

I crushed the copper tube.

Only Sanding.

I have not seen this construction of the buckle. But prototype may be made with this way.

Leather working. The leather material is saddle leather.

Double rollers buckle isn't bad.

Pen case 2

I made normal sized one.

When I cut the edge round, I use coin. This way should be done with dried leather. The wet leather keeps the mark of the coin.

Wet leather's surface is very delicate. At first finish the inside.

I tried carving on the surface. They are basic patterns.

They were tinned with light red then, then weathering with a bit dark red.

At last weathering with a dark purple. Acrylic clear paint was used to finish.

Stitching was too strong to the wet leather in this time.

When I cut the edge round, I use coin. This way should be done with dried leather. The wet leather keeps the mark of the coin.

Wet leather's surface is very delicate. At first finish the inside.

I tried carving on the surface. They are basic patterns.

They were tinned with light red then, then weathering with a bit dark red.

At last weathering with a dark purple. Acrylic clear paint was used to finish.

Stitching was too strong to the wet leather in this time.

Pen case

I tried making pen cases.

I like writing with pencil. So I need a little bigger size of pen case to put new pencil in it. I found leather pencil case kit in the net.

I think that the format isn't enough economical. I designed it is made from 3 pieces. The paper form is for normal sized pen case.

Then cut them from leather. This time vegetable tanned leather for craft was used. It easy to make it a bit longer.

These smaller pieces can be cut from thinner material. The inside is rubbed with a bit water to avoid fluffing. After that, I used chemical one to finish it.

The wood block also was made by me.

Glued the edge. Then guide holes were made.

then stitched.

I think that it's better to stitch dried leather material. This time, they included a little water to finish inside.

Although I brush the edge with water, it doesn't get deep color.

tin the edge !

Not so bad.

I like writing with pencil. So I need a little bigger size of pen case to put new pencil in it. I found leather pencil case kit in the net.

I think that the format isn't enough economical. I designed it is made from 3 pieces. The paper form is for normal sized pen case.

Then cut them from leather. This time vegetable tanned leather for craft was used. It easy to make it a bit longer.

These smaller pieces can be cut from thinner material. The inside is rubbed with a bit water to avoid fluffing. After that, I used chemical one to finish it.

The wood block also was made by me.

Glued the edge. Then guide holes were made.

I think that it's better to stitch dried leather material. This time, they included a little water to finish inside.

tin the edge !

Started leather crafting

A few months ago, I have started leather crafting.

That doesn't relate to my bikes yet.

These became to belt of leather cuffs.

The cuff is constructed wider part and narrower parts.

I tried carving. I noticed that I don't like stamping. So above one is only cutting.

The leather is vegetable tanned one. We can tin it.

The leather material is called saddle leather, too. It isn't easy to extend it.

Using metal rivet as alternative way of stitching is easy. But I don't like that. I mainly use stitching.

The cuffs fits to my wrist. 6 cm of around of wrist is minimum.

That doesn't relate to my bikes yet.

These became to belt of leather cuffs.

The cuff is constructed wider part and narrower parts.

I tried carving. I noticed that I don't like stamping. So above one is only cutting.

The leather is vegetable tanned one. We can tin it.

The leather material is called saddle leather, too. It isn't easy to extend it.

Using metal rivet as alternative way of stitching is easy. But I don't like that. I mainly use stitching.

The cuffs fits to my wrist. 6 cm of around of wrist is minimum.

I made a pair of hand cuff for the first time.

Subscribe to:

Posts (Atom)